Reliable Results: Powder Coating vs Paint for Metal

Powder Coating vs Liquid Paint for Industrial Metal Components

Choosing a coating is not just about price. Instead, it’s about performance, downtime, and service life. For that reason, many industrial teams compare powder coating and liquid paint before they commit.

In general, powder coating gives stronger protection in harsh conditions. However, liquid paint can still make sense in specific cases. So, the right choice depends on how the part will be used.

Quick Overview: The Main Difference

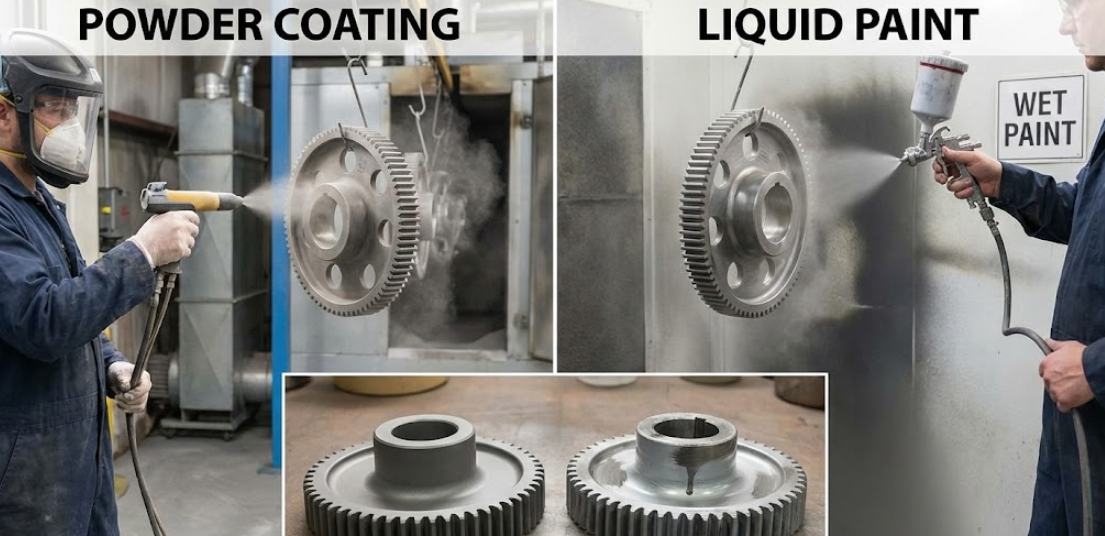

Powder coating uses a dry powder and cures in an oven. As a result, it forms a tough, even layer that resists chips and corrosion. Liquid paint, on the other hand, is a wet coating that air-dries or cures with heat. Because it contains solvents, it can be easier to apply on-site, but it may wear faster in tough environments.

For a simple industry explanation of powder coating, you can reference the Powder Coating Institute (PCI) here: (link).

When Powder Coating Is the Better Choice

Powder coating is a strong option when you need durability first. It also works well when parts see heavy use.

Powder coating is often best for:

- Steel and aluminum parts

- Outdoor or corrosive environments

- High-wear or high-impact applications

- Projects needing long service life

- Parts that benefit from consistent finish quality

Because powder coating cures into a hard film, it typically resists scratches and chipping better than many paint systems. Therefore, it often reduces maintenance and recoating.

When Liquid Paint May Be the Right Fit

Liquid paint still has a place, especially when baking is not possible. For example, some parts can’t handle oven heat. In addition, field repairs often require paint.

Liquid paint may be appropriate for:

- Heat-sensitive parts

- Very large items that can’t fit an oven

- Temporary or low-duty applications

- On-site touch-ups and repairs

- Fast turnaround jobs with minimal prep

So, if you need flexibility or quick repairs, paint can be a practical choice.

Performance Comparison in Real Conditions

Under industrial conditions, powder coating often lasts longer than liquid paint. In many cases, it can last two to five times longer. As a result, it can reduce downtime, maintenance, and recoating costs.

That said, durability still depends on preparation and curing. Therefore, a professional process matters more than the coating label alone.

How to Choose the Right System

Before you decide, consider these questions:

- Will the part be outdoors or exposed to salt, moisture, or chemicals?

- Does it face impact, abrasion, or frequent handling?

- Can the part fit in a curing oven?

- Do you need on-site repair options later?

- What is the target service life?

If durability and long life matter most, powder coating is often the safer bet. However, if you need field repairs or can’t use oven curing, liquid paint may be the better fit.

Get the Best Results Either Way

A good finish starts with good preparation. Proper cleaning and blasting help both systems perform better. In addition, correct curing and quality control reduce early failures.

If you want help choosing the right coating for your parts, Get a Quote (link).

PCI reference link